Inspection Equipment

CMM

With the ZEISS CMM in our facility, we’re able to provide full dimensional report for some precision parts per our customer’s request.

Dial Caliper

Dial caliper is used to measure parts for accuracy. It can be used to measure outside diameter, length, height or thickness of a part. Proto Expedited ensures every part we made is inspected and in-spec.

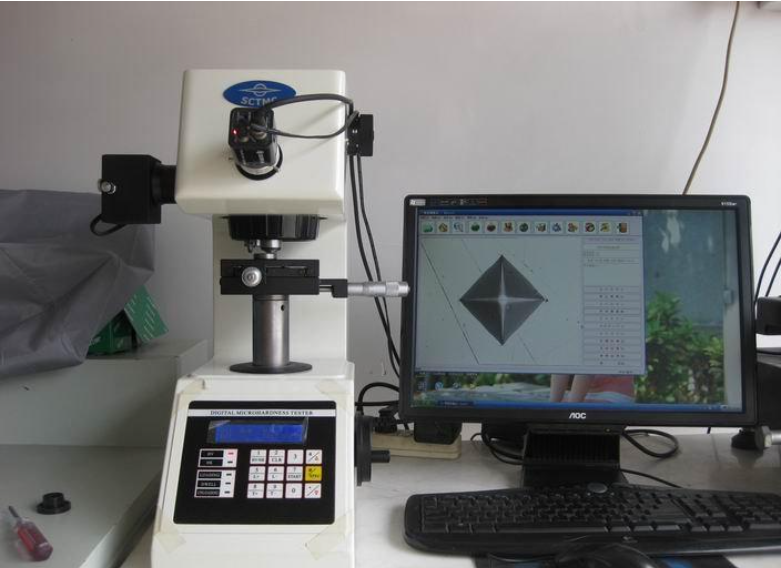

Hardness Tester

This device that indicates the hardness of a material, usually by measuring the effect on its surface of a localized penetration by a standardized rounded or pointed indenter of diamond, carbide, or hard steel.

Height Gauge

Height gauge is precision measuring instrument that use to determine the height of an object or workpiece with extremely high precision and accuracy, or to provide marked locations on the item relative to a reference plane for subsequent use.

Optical Comparator

We use optical comparator to inspect and measure the dimensions of small parts. Images of the part are magnified using illumination sources, lenses and mirrors to make the 2D measurement.