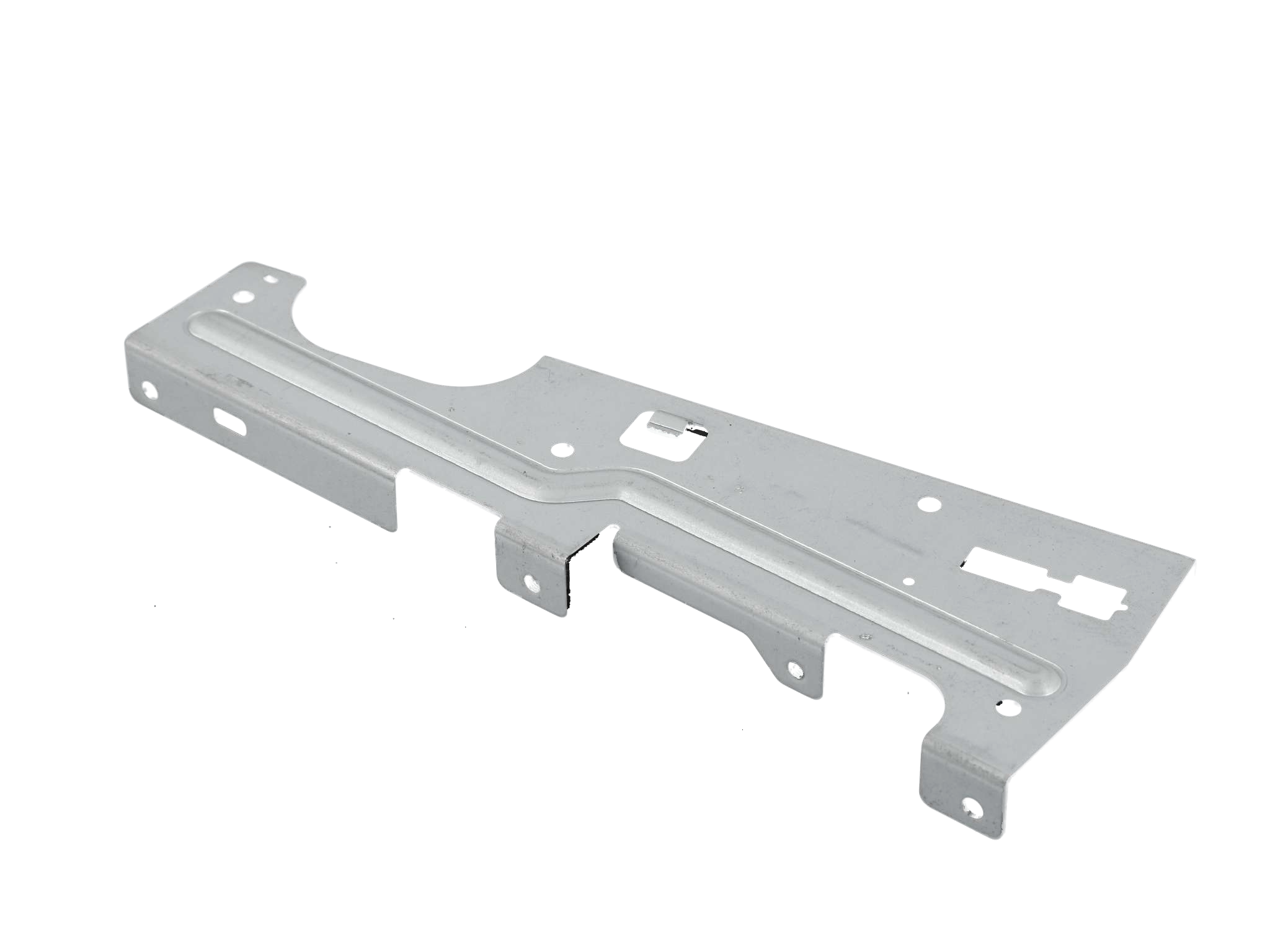

Sheet Metal Fabrication

High Quality

Fast Lead Time

Competitive Pricing

Precision Parts

What is Sheet Metal Fabrication?

Sheet Metal Fabrication is a manufacturing process where sheets of metal are cut and folded into functional parts. The thickness of sheet metal is usually between 0.008″ (0.2mm) and 0.25″ (6.35mm).

So-called sheet metal fabrication has several processes that include cutting, bending and punching, it can be used either in tandem or individually.

We usually use heet metal fabrication to create functional prototypes and end-use parts, it’s all up to your needs.

Our Advantages:

Material Selection

Finishing Options

Thickness Options

High Quality

Laser Cutting

Bending

This is done through the application of force on a workpiece. The force must exceed the material’s yield strength to achieve a plastic deformation. Only then can you get a lasting result in the form of a bend.

Why Metalworking With Proto Expedited

| Aluminum | Steel | Stainless Steel |

| Al5052 | S235 | SS304(L) |

| Al5083 | S355 | SS316(L) |

| Al6061 | ||

| Al6082 |

Available Materials for Sheet Metal Fabrication

Please contact sales@protoexpedited.com if the materials you need are not listed.